Tangential Flow Filtration (TFF) Systems – UF, MF

Your Membrane System Configured Your Way

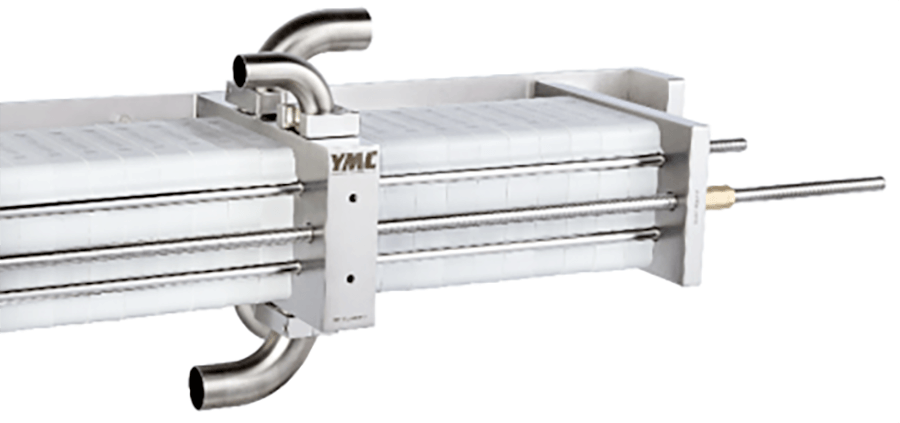

Tangential flow filtration is a method that enables efficient separation and purification of biological products in the biopharmaceutical field. When you combine your preference for membrane supplier and configuration with our design, engineering, and fabrication expertise, you are assured of a tangential flow filtration (TFF) system built to your precise specifications. That’s why YMC TFF systems in both hollow fiber and cassette formats are in operation at the world’s leading biomanufacturers for concentration, purification, and formulation (UF/DF) applications.

You will find no better partner for manufacturing TFF/membrane systems than the team at YMC. Many of our staff members come from the biotech industry, as well as all the major TFF membrane suppliers. We understand fluid dynamics—and the end-to-end requirements of your downstream purification processes.

Customized Systems Are Our Specialty

At YMC, we offer custom tangential flow filtration solutions to meet specific process needs. Our TFF systems include:

- YMC cassette holders are compatible with most major suppliers of cassettes

- Built-in cassette integrity and NWP (normal water permeability) testing

- Steam-in-place capabilities

- Adaptable for diverse scales with cassette capacities including (but not limited to):

- 0.5 – 5 m2

- 2 – 20 m2

- 4 – 40 m2

- 6 – 60 m2

- Fully customizable hollow fiber capacities

- Hazardous location ratings (Cl.1, Div.1, Div.2; ATEX Zone 0, 1, 2)

Our extensive knowledge of membrane technology allows us to deliver systems optimized for filtration of cell cultures, proteins, and other biomolecules. Our solutions for membranes include:

- Hollow fiber systems (UF and MF)

- Flat-sheet cassette systems (UF and MF)

- Cartridge-based direct flow systems

All TFF systems are fully drainable and cleanable.

Superior Flexibility and Performance

All systems are designed and manufactured in compliance to BPE guidelines, as required.

We pride ourselves on the customization we offer. Our tangential flow filtration products are designed to provide a wide range of capabilities. Whether your needs involve cell harvesting, protein purification, or other complex bioprocesses, our tangential flow filtration systems ensure reliable and reproducible results.

Advantages of YMC Tangential Flow Filtration (TFF) Systems

YMC offers tangential flow filtration solutions that are adaptable to your application. With our systems:

- Use your preferred separation device —we aren’t a membrane manufacturer, so we build what you want—not what we want to sell you as a consumable.

- Save costs over proprietary OEM membranes. YMC’s cassette holder design is precision-made by YMC and available for most major cassette formats.

- Implement robust automation and process control through YMC’s smart and flexible user adaptable control system.

- You’ll have a GMP-compliant system built specifically to your process requirements.

- FAT and Turn Over Packages will assure you of a job done right.

Why Choose YMC for Your Tangential Flow Filtration Needs?

At YMC, we are not tied to any particular membrane manufacturer. We configure our tangential flow filtration systems to align with your preferences and the specific flow requirements of your application. Filters are selected and configured based on the unique characteristics of your lab or production environment. Our ability to select the right solutions for you ensures optimal results across all scales of operation.

Columns, Guards and Accessories are only available for purchase online in North America or through our distributors.

To purchase consumables outside North America, please find your local distributor.

For YMC systems’ sales outside of North America and Europe, find your regional office contact information here.